PRODUCTS

To provide customers with cost-effective

Full range of air reservoir, muffler, SCR exhaust aftertreatment system

Jinqu company has a number of engineering machinery, bus manufacturers supporting. The company's "Golden Melody" brand products have sprung up in China's auto parts industry. The company undertakes to map and sample customization business.

RECOMMEND

Hot Product recommend

0201AA0 Aluminum Alloy Gas Cylinder

Small Tianlong Aluminum Alloy Gas Cylinder

3513010-DY799 Aluminum Alloy Gas Cylinder

FAW Series 9803-600 Dual-Aluminum Alloy Gas Cylinder

FAW Series 151 Small - 10 Holes

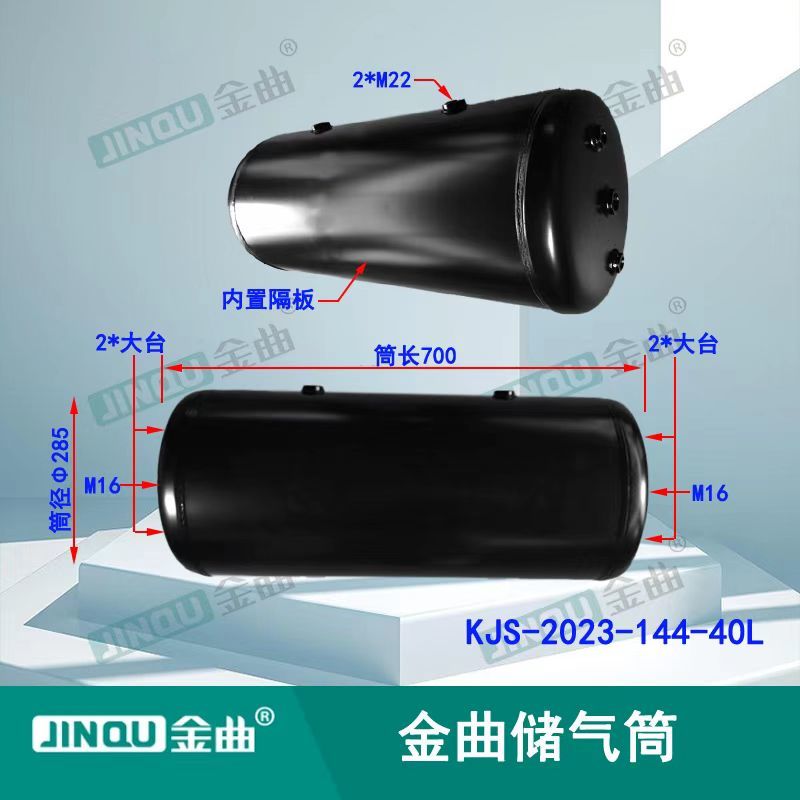

2023-144-40L - Iron Gas Cylinder

The company was established in 2002

The company has more than 20 employees

The company covers an area of 26000 square meters

Partner 900

CUSTOMIZED

The products are suitable for all kinds of commercial vehicles and construction machinery

Cangzhou Jinqu Auto Parts Co., Ltd. was established in July 2002 and is located in the industrial zone of Migezhuang Town, Hejian City, Hebei Province. Is a wholly-owned private enterprise.

The company specializes in the production of muffler (country III), catalytic muffler (country IV, country V, country VI), air reservoir, suitable for all kinds of commercial vehicles and construction machinery.

Cangzhou Jinqu Auto Parts Co., Ltd. has strong technical force. Sophisticated production equipment, detection means perfect. QC/T631-2009 the whole process. The TS16949 standard is the consistent standard of our company's production, supply, sales and after-sales service.

Modern management, high-quality steel raw materials.

Our dedicated R & D team and engineers create innovative solutions for the needs of our business partners.

We have many years of experience in exporting to more than 30 countries.

APPALICATION

Complete muffler product supply, service and customized solutions

Cangzhou jinqu automotive co.,ltd has been with a number of construction machinery, bus manufacturers supporting. The company's "Golden Melody" brand products have sprung up in China's auto parts industry. The company undertakes to map and sample customization business. If your industry needs wholesale muffler solutions, please feel free to contact us, whether it is product consultation, technical support or after-sales service, we will be happy to provide you with professional and timely help.

Standard stainless steel sheet metal parts

Brand carrier

Brand coating

Efficient particulate matter capture

Good durability

efficient transformation