Sharp Power - DOC Component

The DOC (Diesel Oxidation Catalyst) component catalytic muffler is the core component of diesel vehicle exhaust treatment systems. Its functions, applications, and uses are as follows:

**Primary Functions:**

- By utilizing an internally coated catalyst—such as vanadium pentoxide (V₂O₅)—the DOC converts harmful pollutants in diesel exhaust, including carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx), into harmless substances like carbon dioxide (CO₂), nitrogen gas (N₂), and water (H₂O).

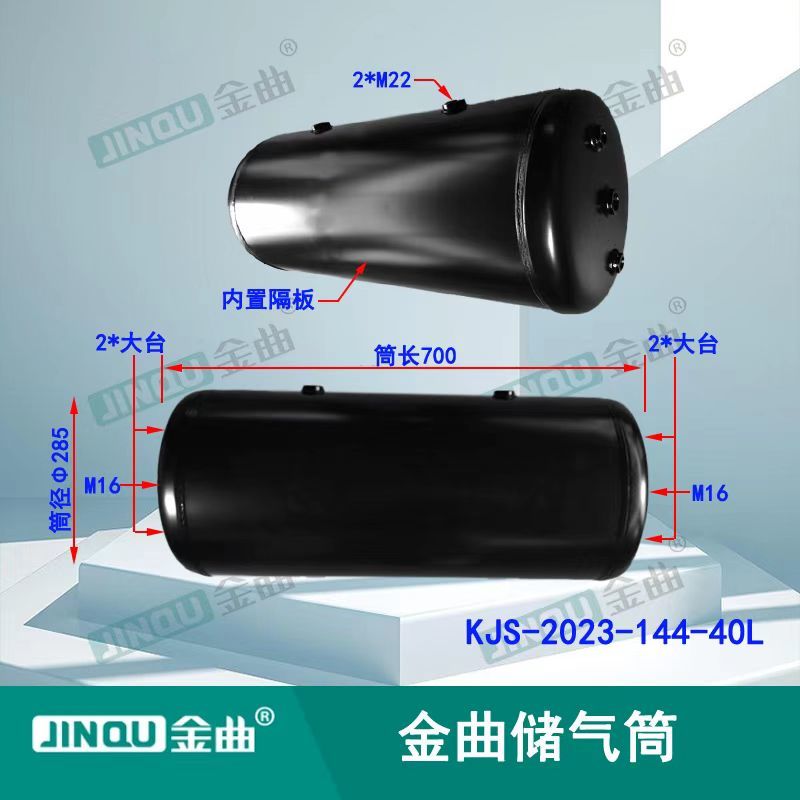

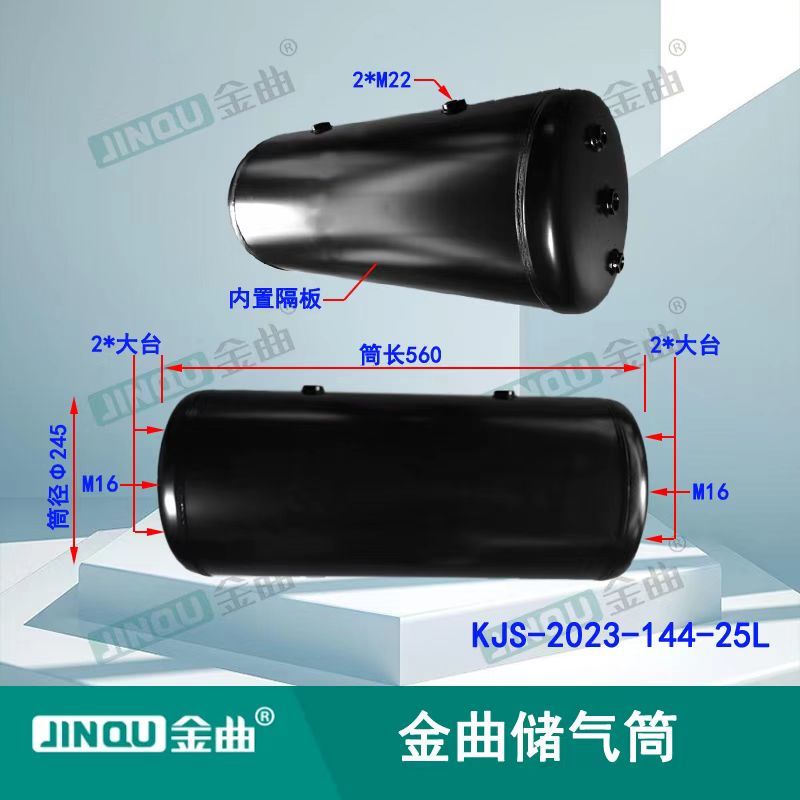

- Combined with the muffler’s structural design—featuring components like porous tubes, baffles, and expansion chambers—the DOC reduces exhaust noise through sound wave reflection, interference, and energy absorption by acoustic materials such as glass fiber, thereby enhancing driving comfort.

**Primary Applications:**

- Designed to meet China IV emission standards and beyond, the DOC significantly lowers pollutant levels in diesel vehicle exhaust, helping vehicles pass environmental inspections with ease.

- It optimizes exhaust backpressure, minimizing engine power loss.

- By purifying exhaust gases, the DOC also mitigates the corrosive effects of high-temperature, harmful emissions on both the engine and exhaust system, ultimately extending the lifespan of critical components.

**Application Scenarios:**

- **Heavy-duty trucks and buses:** Ideal for handling high-volume exhaust emissions while meeting stringent environmental requirements for long-haul transportation.

- **Light commercial vehicles:** Such as urban logistics trucks, where balancing performance with compliance to emission regulations is crucial.

- **Non-road machinery:** Including construction equipment and agricultural machines, designed to tackle challenging operating conditions and ensure effective exhaust treatment.

**Technical Advantages:**

- Employs a cocoon-shaped cordierite honeycomb ceramic substrate, dramatically increasing the catalyst’s surface area and boosting reaction efficiency.

- Features a dual-catalyst design—such as an SCR system—to achieve staged purification, ensuring superior NOx conversion rates.

- The urea injection system works synergistically with a gas-liquid mixer, enabling uniform dispersion of ammonia throughout the exhaust stream, thereby enhancing SCR reaction efficiency.

- Integrates catalytic and muffling functions into a single compact unit, making it easier to install even in vehicles with limited space.