Product Series

Contact Us

E-mail:

Phone/WeChat:

Address:

Hebei Hejian Economic Development Zone Migezhuang Industrial Park Huayang Street and Liumiao Road intersection 20 meters west

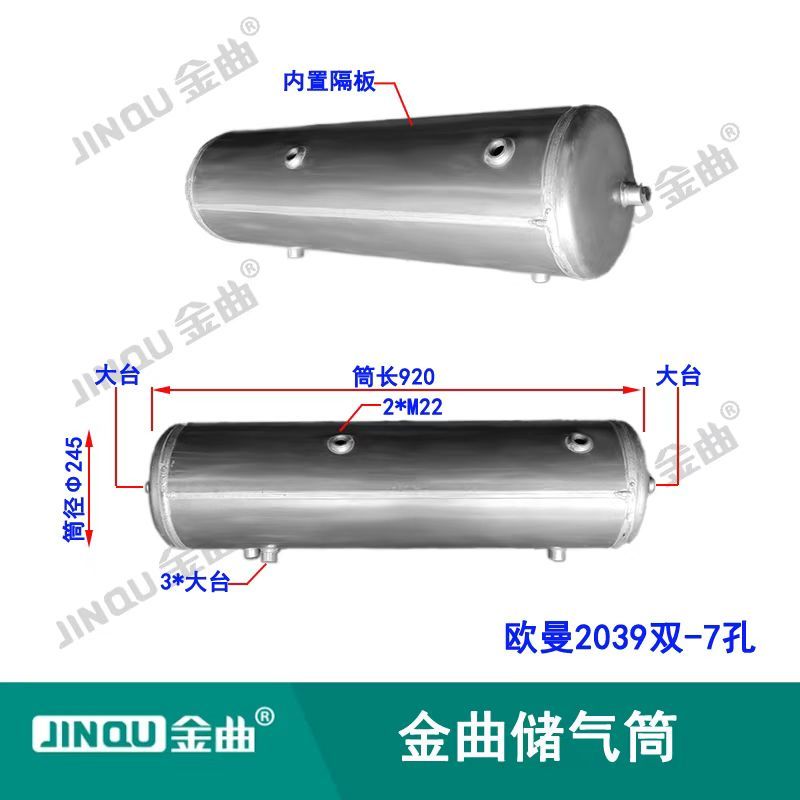

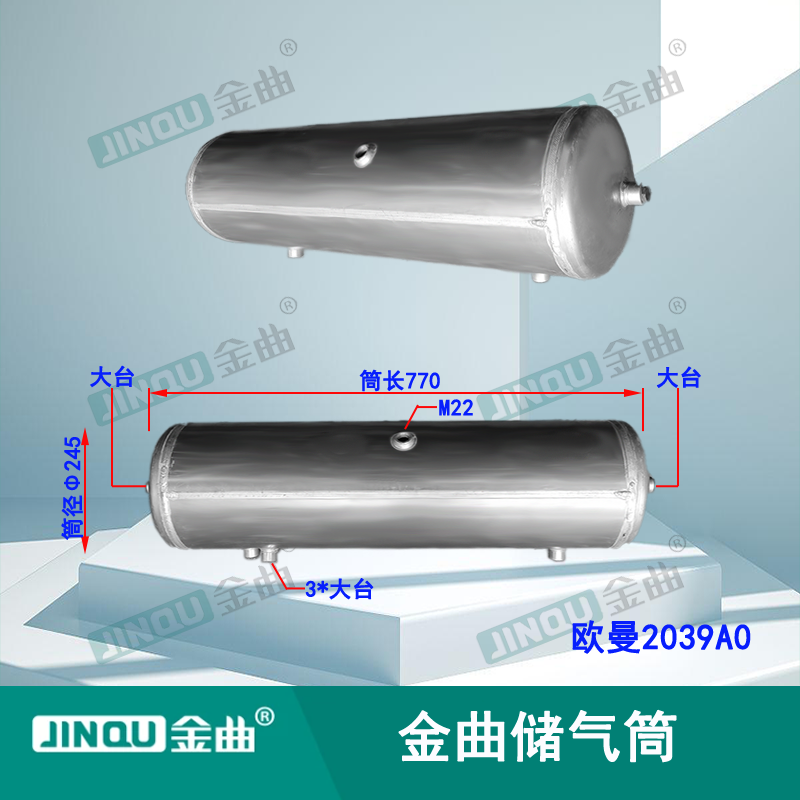

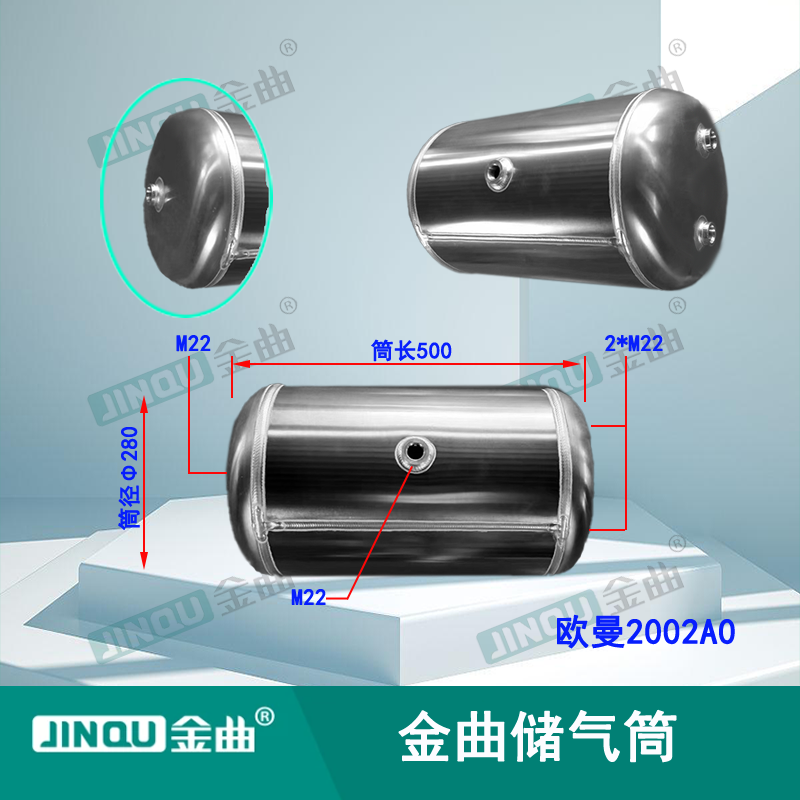

Ouman Series

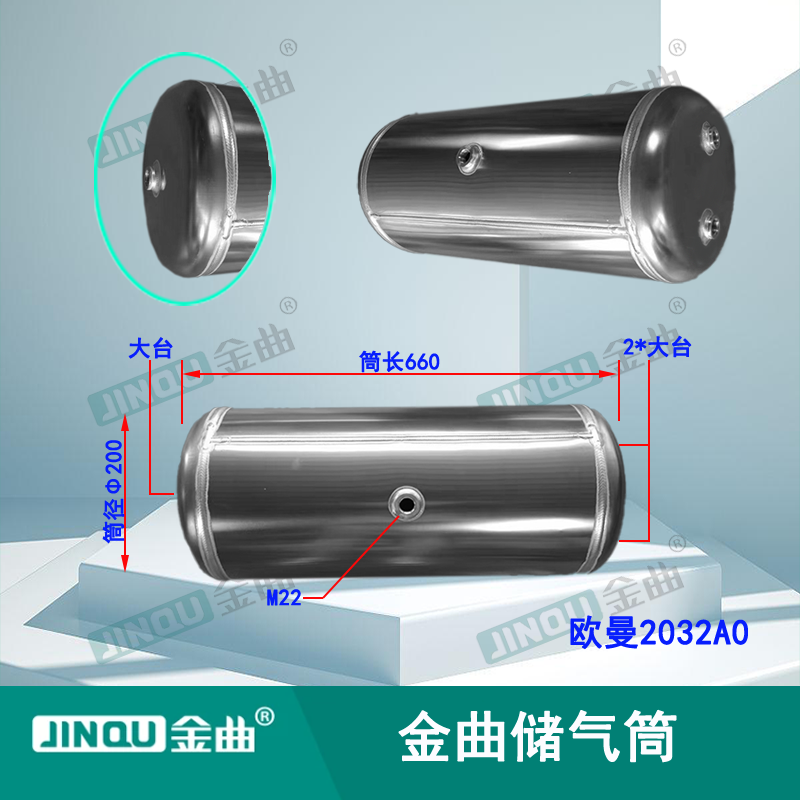

0201AA0 Aluminum Alloy Gas Cylinder

Aluminum alloy gas cylinders are gas storage devices whose material thickness is determined based on the rated working pressure and volume, primarily used for storing high-pressure gases.

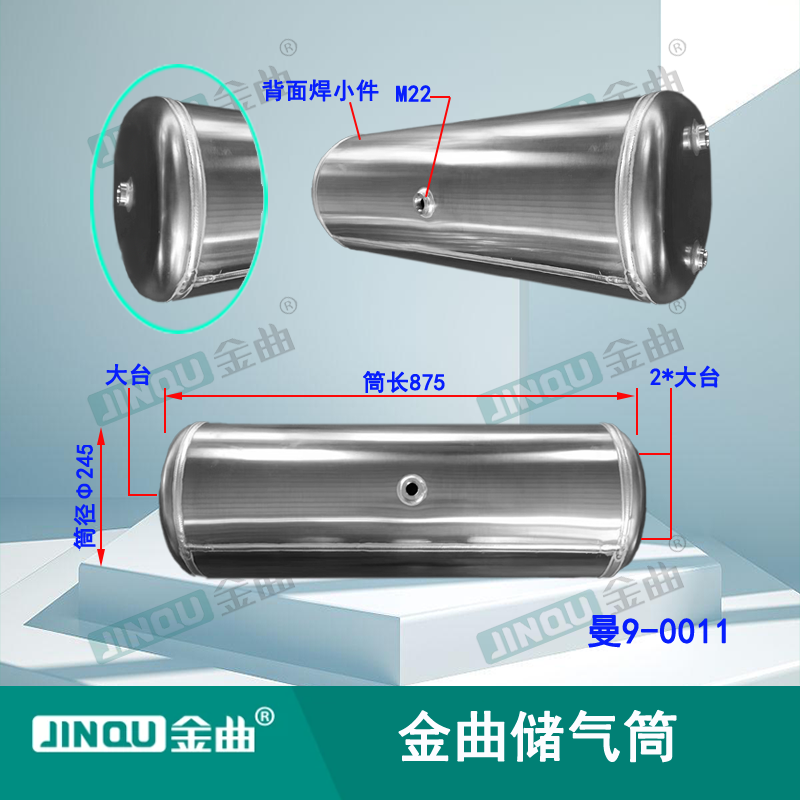

Man 9-0011 Aluminum Alloy Gas Cylinder

The MAN 9-0011 aluminum alloy air reservoir is a critical component used on vehicles in the Ouman series to store compressed air. Its primary functions include:

- **Energy Storage and Air Supply**: It stores the compressed air generated by the air compressor, providing a reliable and ample air supply to vehicle systems such as the braking system and air horns, ensuring these components operate smoothly and efficiently.

- **Impurity Filtration**: Dust, water vapor, and oil particles present in the air naturally settle within the reservoir, effectively filtering out impurities. This helps protect the air lines and connected equipment from damage, ultimately extending the lifespan of key components.

- **Pressure Stabilization**: The compressed air output from the air compressor can be unstable in pressure. The reservoir acts as a buffer, smoothing out fluctuations and delivering a steady air supply, which ensures consistent performance of air-consuming devices and minimizes failures caused by pressure variations.

- **Cooling and Moisture Separation**: After being compressed by the air compressor, the air temperature rises significantly. The reservoir allows the compressed air to cool down internally, promoting easier condensation of moisture. Additionally, cooling increases air density, enabling the reservoir to store more air efficiently.

- **Weight Reduction**: Compared to traditional iron reservoirs, the aluminum alloy construction is significantly lighter, reducing the overall vehicle weight. This not only enhances fuel efficiency but also improves transportation performance.

- **Corrosion Resistance**: Aluminum alloys are highly resistant to rust and corrosion, preventing iron particles from contaminating the air system and damaging vehicle components. As a result, the reservoir boasts a longer service life and lower maintenance costs.

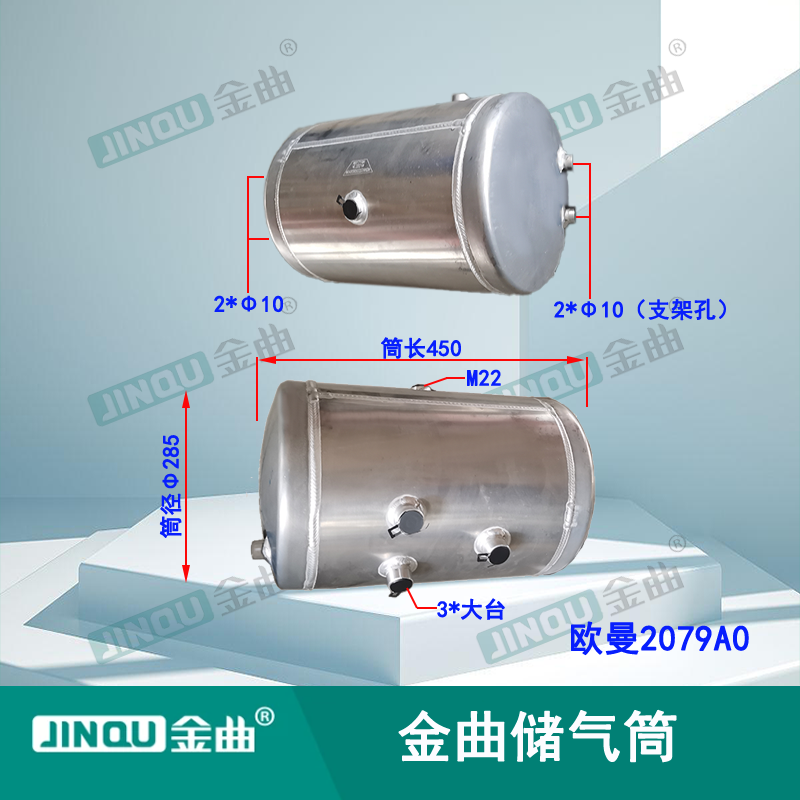

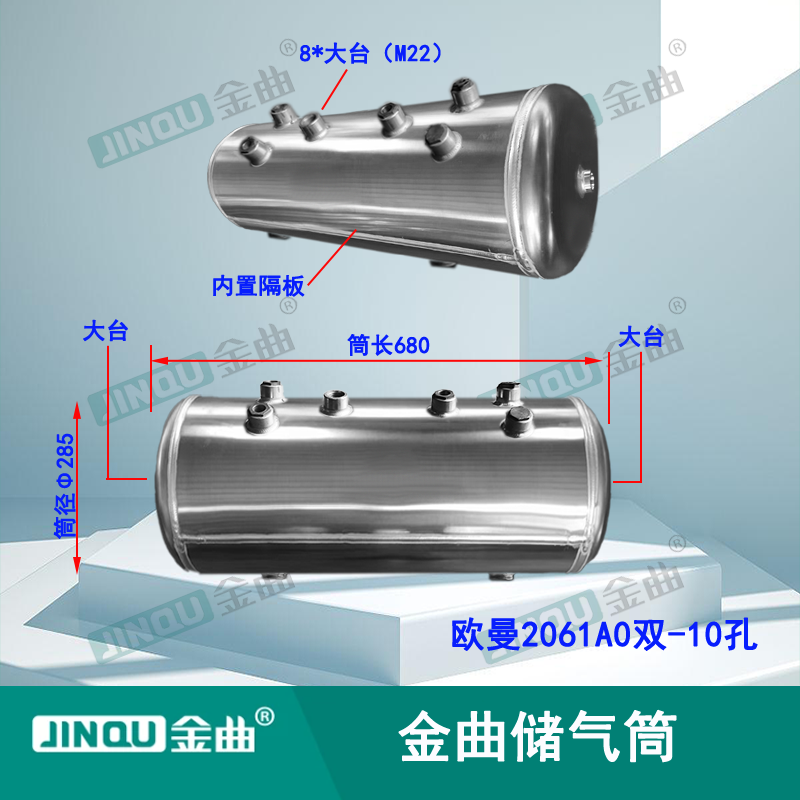

Ouman 2061A0 Dual-10-Hole Aluminum Alloy Air Tank

The Ouman 2061A0 Dual-10-Pore Aluminum Alloy Air Tank primarily serves the following functions:

- **Energy Storage and Air Supply**: It stores compressed air generated by the air compressor, providing a stable air source for vehicle systems such as the service brake, parking brake, pneumatic clutch, and air horns. This ensures that these components receive sufficient air pressure promptly when needed, guaranteeing smooth and reliable vehicle operation.

- **Filtration and Purification**: Moisture, dust, oil, and other impurities contained in compressed air naturally settle at the bottom of the air tank due to gravity, effectively acting as a preliminary filtration step. This prevents contaminants from entering downstream air system components (such as brake valves and pipelines), reducing wear and tear on parts, minimizing failure risks, and extending the overall lifespan of the air system.

- **Pressure Stabilization and Buffering**: The output pressure from the air compressor can fluctuate. By utilizing its volume capacity, the air tank helps buffer these pressure variations, delivering a more consistent and stable air supply. This prevents sudden pressure changes that could destabilize air-consuming devices—especially the braking system—thereby enhancing operational reliability.

- **Cooling and Condensation**: After being compressed by the air compressor, the air temperature rises significantly. As it enters the air tank, the cooler environment allows the hot air to lose heat, promoting the condensation of water vapor into liquid form. This process further purifies the compressed air by removing moisture, ultimately reducing the risk of corrosion within the air system caused by water ingress.