Product Series

Contact Us

E-mail:

Phone/WeChat:

Address:

Hebei Hejian Economic Development Zone Migezhuang Industrial Park Huayang Street and Liumiao Road intersection 20 meters west

Other series

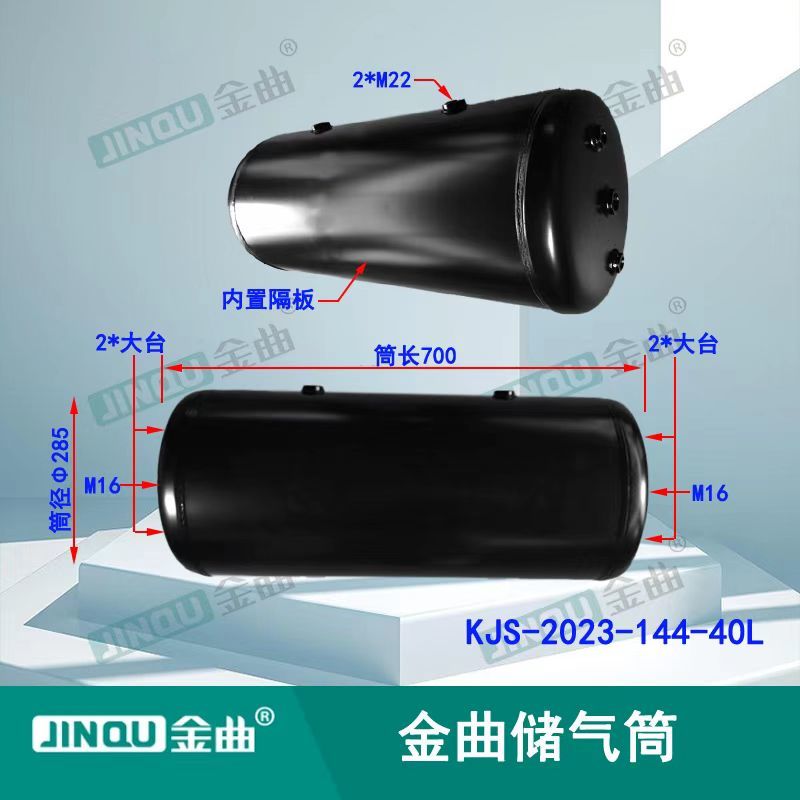

2023-144-40L - Iron Gas Cylinder

The 2023-144-40L iron air receiver tank serves similar functions, purposes, and applications as a typical iron air receiver tank:

- **Energy Storage**: It stores a certain amount of compressed air, which can be quickly released when pneumatic equipment demands high gas output, thereby reducing the need for frequent compressor starts. This not only extends the compressor's lifespan but also lowers energy consumption.

- **Pressure Stabilization**: By buffering pressure fluctuations in the compressed air system, the tank helps maintain a steady system pressure, ensuring smooth operation of connected pneumatic devices.

- **Cooling and Moisture Removal**: After compressed air enters the tank, its temperature drops, causing moisture to condense into water droplets that settle at the bottom. Regular draining of this accumulated water improves the quality of the compressed air.

- **Noise Reduction**: The tank also provides some sound insulation, helping to minimize noise pollution from the compressed air system.

**Applications**:

- **Industrial Sector**: Supplies stable compressed air to various pneumatic devices, such as pneumatic tools in machinery manufacturing, jet looms in the textile industry, and filling machines in the food industry. It’s also widely used in pneumatic conveying systems and automated control applications.

- **Automotive Industry**: Stores compressed air to power critical systems like automotive braking systems, pneumatic seat adjustments, and air-powered doors and windows, ensuring reliable performance of these components.

- **Other Fields**: In agricultural production, it serves as a power source for farming machinery; in shipbuilding and marine engineering, it acts as an energy storage device; and in aerospace, it is used to store essential gases like oxygen, nitrogen, and compressed air required for aircraft and spacecraft operations.

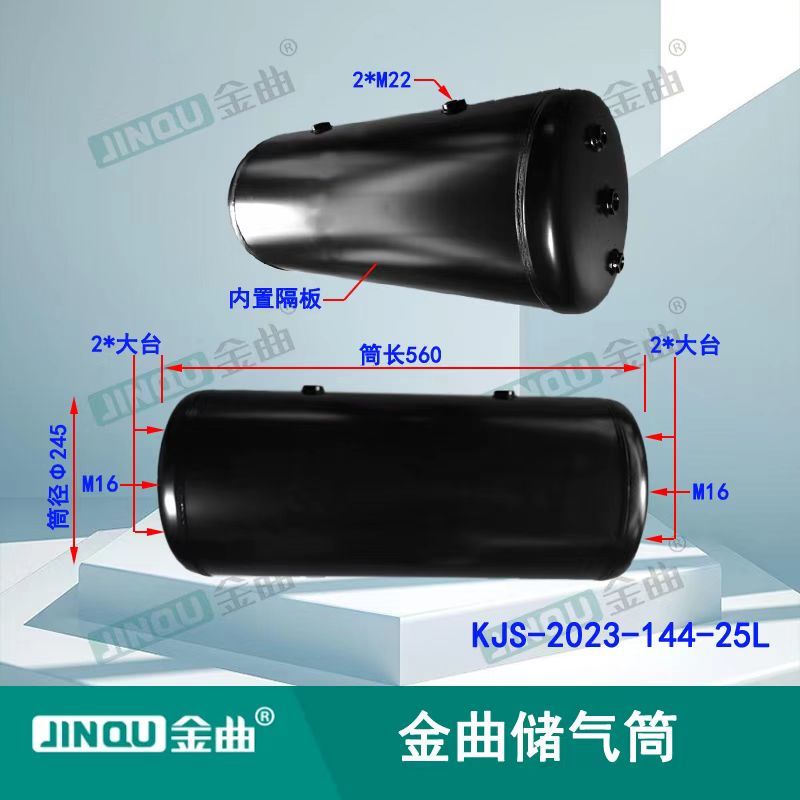

2023-144-25L - Iron Gas Cylinder

The 2023-144-25L iron air receiver tank serves similar functions, purposes, and applications as typical iron air receivers:

- **Energy Storage**: It stores a certain amount of compressed air, which can be quickly released when pneumatic equipment demands high gas flow, thereby reducing the need for frequent compressor starts. This not only extends the compressor's lifespan but also lowers energy consumption.

- **Pressure Stabilization**: By cushioning pressure fluctuations in the compressed air system, the tank helps maintain a steady system pressure, ensuring smooth operation of connected pneumatic devices.

- **Cooling and Moisture Removal**: After compressed air enters the tank, its temperature drops, causing moisture to condense into water droplets that settle at the bottom. Regular draining of this accumulated water improves the quality of the compressed air.

- **Noise Reduction**: The tank also provides some sound insulation, helping to minimize noise pollution from the compressed air system.

**Applications**:

- **Industrial Sector**: Supplies stable compressed air to various pneumatic devices, such as pneumatic tools in machinery manufacturing, jet looms in the textile industry, and filling machines in the food industry. It’s also widely used in scenarios like pneumatic conveying and automated control systems.

- **Automotive Industry**: Stores compressed air to power critical systems in vehicles, including braking systems, pneumatic seat adjustments, and air-operated doors and windows, ensuring reliable performance of these components.

- **Other Fields**: In agricultural production, it serves as a power source for farming machinery; in shipbuilding and marine engineering, it acts as an energy storage device; and in aerospace applications, it is used to store essential gases like oxygen, nitrogen, and compressed air required for aircraft and spacecraft operations.

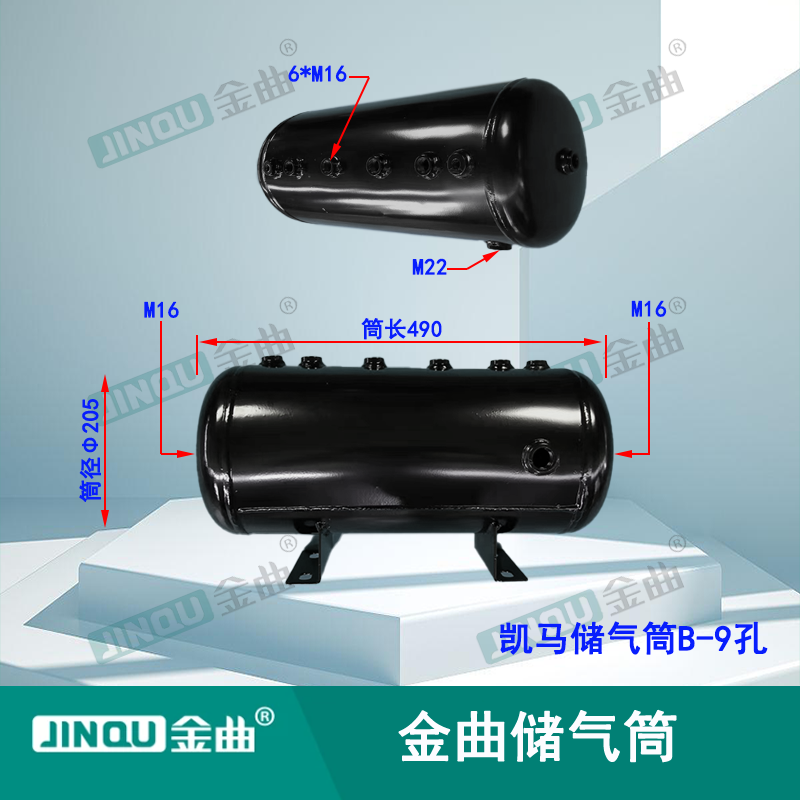

TD95A9360910-30 - Iron Gas Cylinder

The functions, uses, and applications of the TD95A9360910-30 iron air receiver tank are as follows:

**Functions:**

- **Energy Storage:** The tank stores compressed air pumped by the air compressor, meeting the high-demand air requirements of critical systems such as car brakes and horns. Often, the air volume produced by the compressor alone is insufficient, making energy storage via the receiver tank essential.

- **Filtration:** Impurities in compressed air—such as dust, water molecules, and even oil that may enter due to compressor malfunctions—gradually settle at the bottom of the tank because of their heavier weight, effectively filtering out these contaminants and reducing wear on vehicle components.

- **Pressure Stabilization:** The up-and-down movement of the air compressor’s piston causes fluctuations in the compressed air delivered to the vehicle’s pneumatic system. The receiver tank helps stabilize this airflow, ensuring a consistent output pressure for reliable operation.

- **Cooling:** Compressed air generated by the air compressor tends to increase in temperature. The receiver tank plays a role in lowering this temperature, improving gas storage efficiency while also aiding in the separation and removal of moisture.

**Uses and Applications:**

- **Automotive Industry:** Primarily used to store compressed air, providing a reliable power source for various automotive systems, including brake systems, pneumatic seat adjustments, and air-powered doors and windows. For instance, commercial vehicles like trucks and buses rely on the receiver tank to maintain stable air pressure in their pneumatic braking systems, ensuring safe and dependable braking performance.

- **Industrial Sector:** In industrial equipment that depends on compressed air as an energy source, the receiver tank serves to store and regulate compressed air supply. It helps manage peak air consumption demands, ensuring a steady and uninterrupted flow of air to pneumatic tools, valve controls, and other air-driven machinery.

TD95A9360910-40L Iron Air Receiver Tank

The TD95A9360910-40L primarily serves the following functions:

- Energy Storage: It stores compressed air pumped by the air compressor, providing a sufficient air supply for vehicle braking systems, air horns, and other pneumatic devices. When these devices require air, the tank delivers it promptly, ensuring their smooth operation and preventing interruptions caused by insufficient air from the compressor.

- Filtration: Impurities such as dust, water vapor, and oil particles in the compressed air are denser than air, so they settle at the bottom of the air receiver. This natural sedimentation acts as an effective filtration mechanism, improving the quality of the compressed air and reducing damage to the air system and connected equipment. As a result, the lifespan of critical components is extended.

- Pressure Stabilization: The compressed air output from the air compressor often fluctuates in pressure. The air receiver helps buffer and stabilize this pressure, delivering a consistent airflow that ensures reliable operation of pneumatic devices and minimizes failures caused by pressure variations.

- Cooling: After being compressed by the air compressor, the temperature of the air rises significantly. The air receiver allows the compressed air to cool down as it sits inside, promoting easier condensation of moisture. Additionally, cooling increases air density, thereby enhancing the storage capacity of the receiver and maximizing the amount of air it can hold.

Hualing Small - 3-Port Iron Air Receiver Tank

Here are the functions and roles of the Hualing Small-3 Hole System:

- **Energy Storage**: It stores sufficient compressed air, providing a stable air supply to vehicle braking systems, air horns, and other pneumatic devices, ensuring their proper operation.

- **Filtration**: After air enters the receiver tank, dust and moisture settle at the bottom due to gravity, effectively filtering the compressed air and preventing impurities from entering the air system—thus protecting connected equipment.

- **Pressure Stabilization**: The compressed air output from the air compressor can be unstable in pressure. The receiver tank helps buffer and stabilize this airflow, delivering a consistent air pressure that ensures reliable performance of pneumatic devices.

- **Cooling**: When outside air is compressed by the air compressor, its temperature rises significantly. The receiver tank allows the compressed air to linger inside, naturally cooling down and enabling moisture within the air to condense more easily—thereby improving the overall quality of the compressed air.

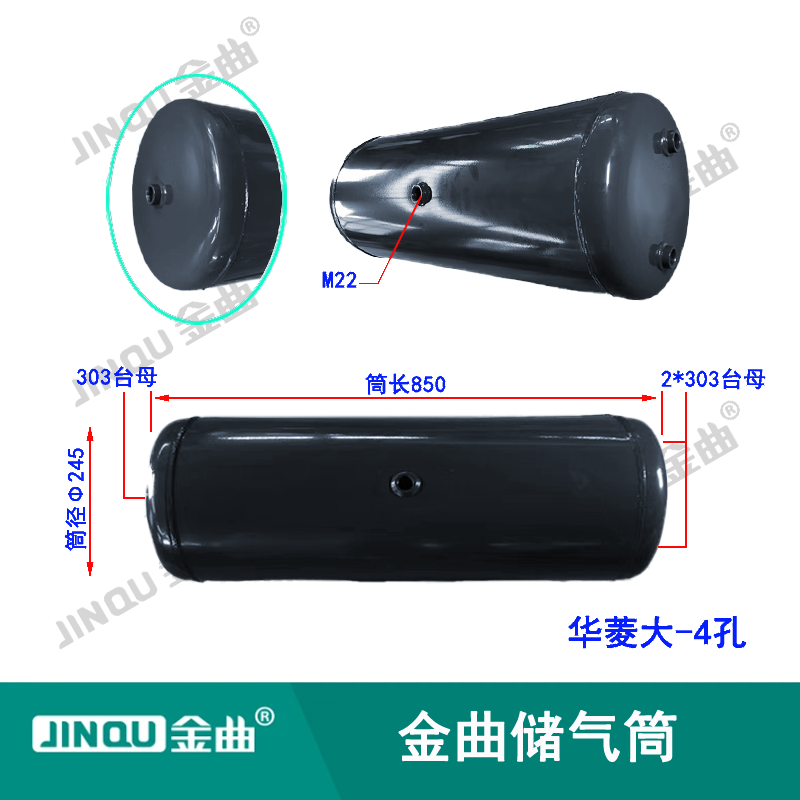

Hualing Large 4-Port Iron Air Storage Tank

Hualing D-4: Functions and Features

- Energy Storage: Stores sufficient compressed air to provide a stable air supply for vehicle braking systems, air horns, and other pneumatic devices, ensuring their proper operation.

- Filtration: As air enters the air reservoir, dust and moisture naturally settle at the bottom of the tank due to gravity, providing an initial filtration process that minimizes impurities entering the air system and protecting connected equipment.

- Pressure Stabilization: The compressed air output from the air compressor can fluctuate in pressure. The reservoir acts as a buffer, smoothing out these fluctuations and delivering a steady, consistent air pressure to maintain reliable performance of pneumatic devices.

- Cooling: After being compressed by the air compressor, ambient air heats up significantly. The reservoir allows the compressed air to linger inside, enabling natural cooling and helping moisture within the air condense more effectively—thus improving the overall quality of the compressed air.

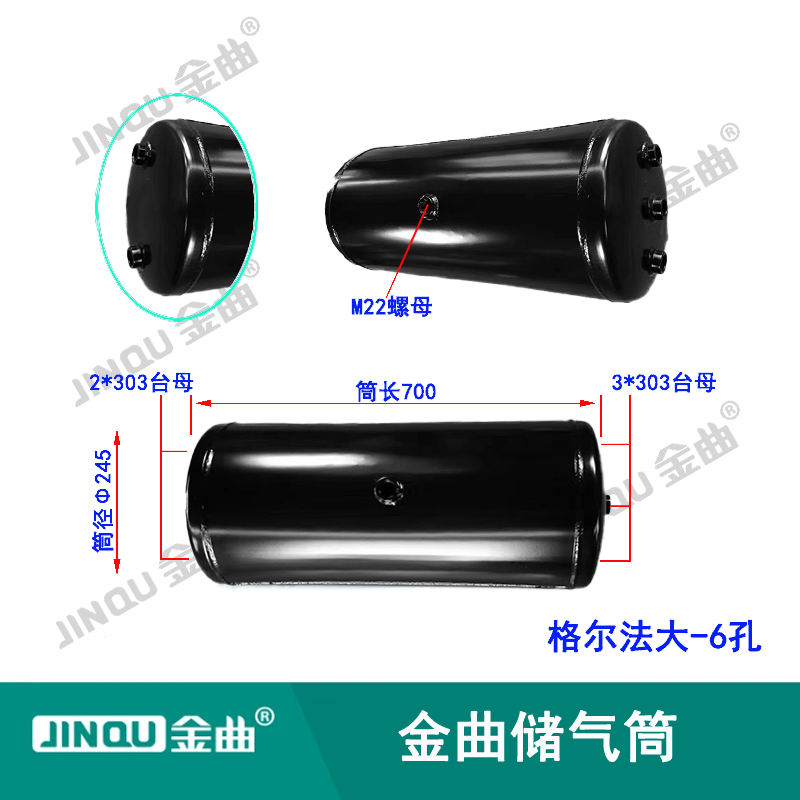

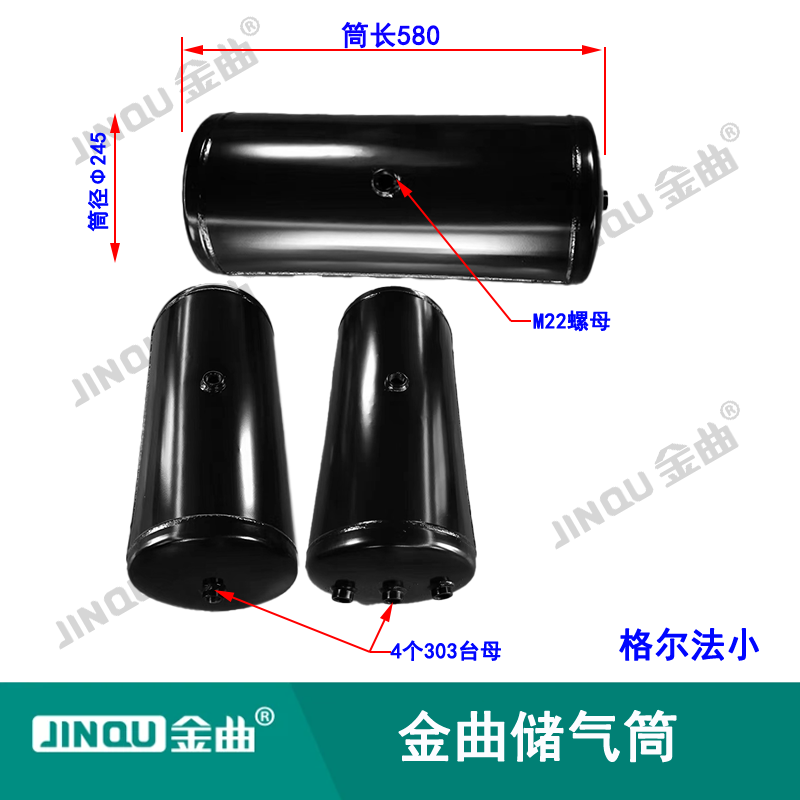

Cangzhou Jinqu Ge'er's childhood friend—Tie Chuciqitong serves several key functions and applications:

- **Storing Compressed Air**: The air receiver tank is designed to store the compressed air generated by the air compressor, providing a steady supply of air for critical systems such as the vehicle’s braking system and horn system. This ensures that these systems have sufficient air pressure to operate reliably.

- **Pressure Stabilization**: When air is pumped into the vehicle via the air compressor, the up-and-down motion of the compressor’s piston creates highly unstable compressed air flow. The air receiver tank helps stabilize this fluctuating airflow, maintaining consistent pressure within the pneumatic system.

- **Filtration and Drainage**: Compressed air often contains impurities like moisture, dust, and oil. As the air passes through the air receiver tank, these contaminants settle at the bottom. The tank is equipped with a drain valve at its base, allowing easy removal of these impurities and ensuring the smooth operation of air-powered equipment, such as the braking system.

- **Cooling**: Ambient air drawn into the compressor undergoes compression, causing its volume to decrease significantly while generating heat. The air receiver tank plays a crucial role in cooling the compressed air, increasing its density and enabling it to store more air efficiently. Additionally, cooling helps facilitate the condensation and separation of moisture from the air.

- **Shock and Vibration Absorption**: The interior of the air receiver tank is typically fitted with shock absorbers or other cushioning components, which help mitigate the impact and vibrations produced by the braking system. This protects sensitive components from damage and enhances the overall durability of the system.